- 35Industry renowned brandStamping machine equipment

- 28Years of industry experienceProfessional Engineer Team

- ± 0.005mm Product size accuracy

- CPK≥1.67 Key Features

ONLINEService Hotline:15964992151/0532-86620382

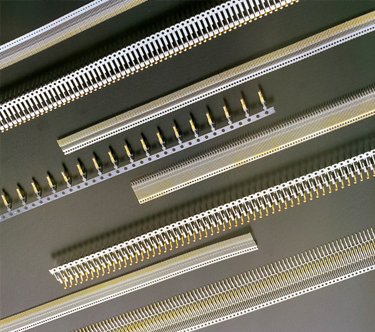

We currently have 15 high-speed precision stamping machines: 4 KYORI 30T machines from Japan; Japan DOBBY 45T 2 units; Taiwan MINGXU 45T 5 units; Zhejiang Taiyida 80T 2 units; Taiwan Jinfeng 150T 2 units. Precision molds: 138 sets; Precision grinding machines: 11 units; Precision milling machines: 3 units; Precision wire cutting: 3 units; Precision discharge: 8 units, providing technical services such as production of precision stamping molds and parts, injection molding molds and parts, and processing and manufacturing.

The company implements IATF16949, ISO14001, and ISO45001 system management and has established a system of "first piece inspection, process inspection, process inspection, finished product inspection, and factory inspection" to ensure that products meet quality, environmental protection, and safety requirements.

The company has experienced process engineers, product designers, structural engineers, and other design engineers in automotive and home appliance parts. Simultaneously participate in the design and development of customer products and molds, solve problems for customers simultaneously, and receive unanimous praise and trust from customers.

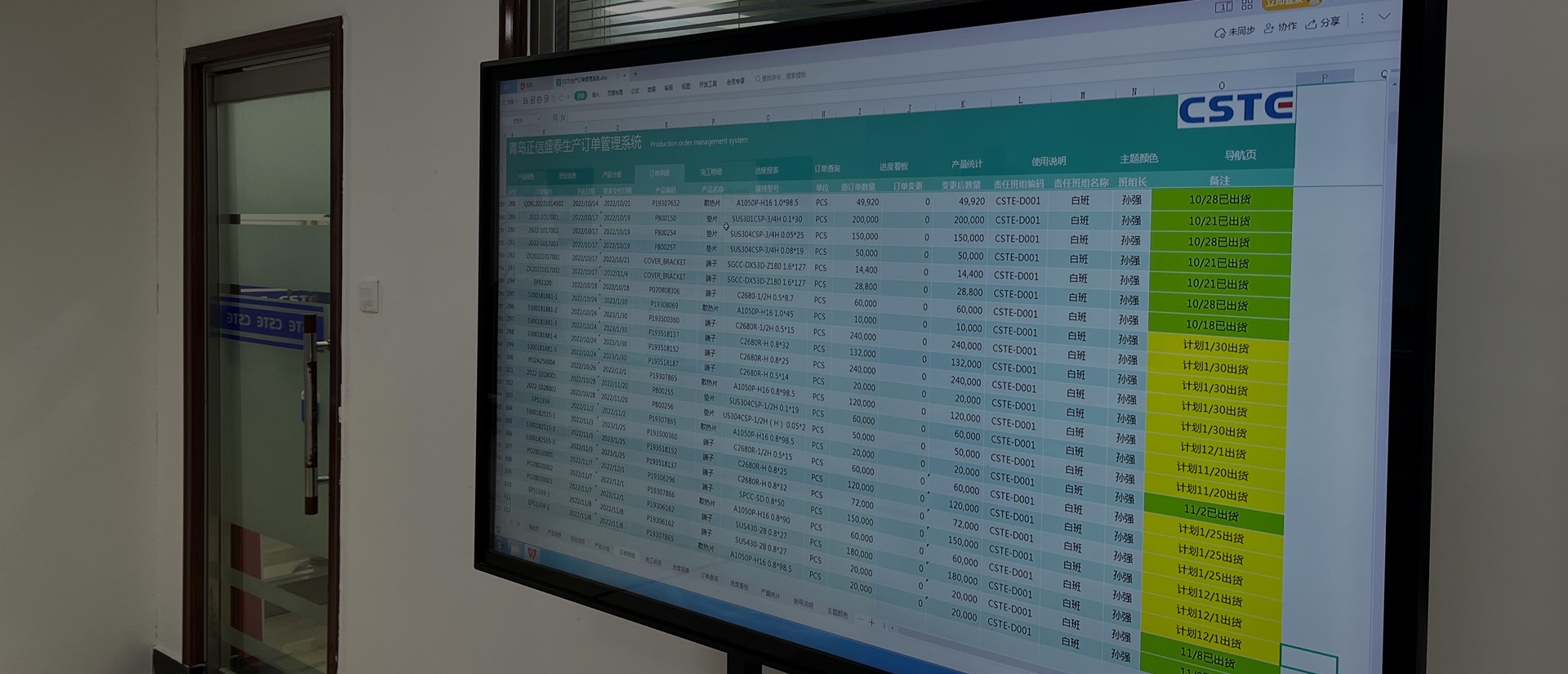

The company has introduced the UFIDA ERP management system, which enables full process information management from customer order import to product outbound

Equipment configuration and production capacityEquipment Capacity

Equipment Capacity

quality controlQuality Control

Quality Control

design abilityDesign Ability

Design Ability

Production managementProduction Management System

Production Management System

development and designDevelopment

development and designDevelopment

development and designDevelopment

CSTE engineers design and develop products based on customer usage requirements, including material selection, process implementation, quality control, and environmental requirements.

prototype buildmachining

prototype buildmachining

prototype buildmachining

Can assist customers in the production of manual samples for verifying the conformity assessment of customer product applications.

mould designMold manufacturing

mould designMold manufacturing

mould designMold manufacturing

Engineers adhere to the principle that product quality is designed, and design high-precision continuous molds according to customer requirements to meet their application needs.

ManufacturingTechnical Training

Manufacturingmanufacturing

Manufacturingmanufacturing

Stamping and machining equipment, experienced engineers in the industry, and comprehensive quality control capabilities continue to provide customers with products and services.

Surface TreatmentSurface treatment

Surface TreatmentSurface treatment

Surface TreatmentSurface treatment

Provide surface treatment processes for products that meet customer needs, including application solutions for nickel plating, gold plating, silver plating, tin plating, zinc plating, and surface anodizing.

Logistics and PackagingLogistics Packaging

Logistics and PackagingLogistics Packaging

Logistics and PackagingLogistics Packaging

Design packaging methods with product protection based on product characteristics requirements to prevent abnormal product quality during the product logistics process.

ONLINEService Hotline:15964992151/0532-86620382

1) The level of precision machining te···

Qingdao Credit Standard Technology Co.,Ltd. is a manufacturer of precision metal and plastic parts. Our core technical team focuses on precision terminals, precision hardware components, and heat sinks (plates). Develop motor enameled wire crimping terminals and industrial electronic control components, and supply them to the global motor manufacturing industry; Develop wiring harness terminals for automotive customers and supply them in bulk.

Service Hotline

WeChat customer service